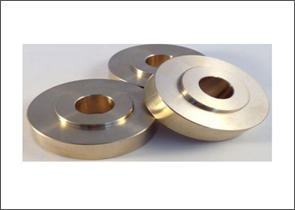

The C66800 Manganese Bronze alloy possess good hot and cold workability and forging ability. It is fabricated using the process of bending, coining, rawing and upsetting, hot forging and pressing, knurling, roll threading, shearing, spinning, swaging, and stamping.

Typical Uses :

• Industrial : Gears, Sealing Rings, Thrust Bearings, Bushings, Cams, Spindles, Bearings, Idler Pins, Connecting Rods, Drive Shafts, Valve Seats, Sleeve Bearings, Piston Heads.

• Marine : Pump Parts, Hardware, High Strength

The C66800 Manganese Bronze alloy possess good hot and cold workability and forging ability. It is fabricated using the process of bending, coining, rawing and upsetting, hot forging and pressing, knurling, roll threading, shearing, spinning, swaging, and stamping.

Typical Uses :

• Industrial : Gears, Sealing Rings, Thrust Bearings, Bushings, Cams, Spindles, Bearings, Idler Pins, Connecting Rods, Drive Shafts, Valve Seats, Sleeve Bearings, Piston Heads.

• Marine : Pump Parts, Hardware, High Strength

Specifications |

Designation |

UNS |

C67300 |

UNS |

C67400 |

UNS |

C67420 |

|

Cu |

Al |

Fe |

Pb |

Mn |

Ni |

Si |

Sn |

Zn |

Min./Max. |

60.0-63.0 |

0.25 |

0.35 |

0.5 |

2.0-3.5 |

0.25 |

.50-1.5 |

0.3 |

Rem. |

Nominal |

61.5 |

- |

- |

- |

2.7 |

- |

1 |

- |

- |

Density |

0.300 lb/in3 |

Melting Range |

1690 – 1730 oF |

Coefficient of Expansion |

(68 to 572oF) 11 ?in/in oF |

Thermal Conductivity |

55 Btu/ft h oF |

Electrical Conductivity |

21 % IACS |

Electrical Resistivity |

54 ? (circ mil/ft) |

Relative Magnetic Permeability |

<1.02 |

Coefficient of Friction |

0.15 |

ROUND RODS |

8mm To 70 mm |

HEX |

10mm To 60mm |

SQUARE |

10mm To 60mm |

FLAT |

10mm Min Thickness and max Width 120mm |

BILLETS |

Up to 200 mm |

INGOTS |

As per Specification |

The C67000 Manganese Bronze B is the high in strength alloy that possess hot and cold workability with good forging ability. The alloy is manufactured using the process of bending, coining, drawing and upsetting, hot forging and pressing, knurling, roll threading, shearing, spinning, swaging, and stamping.

The C67000 Manganese Bronze B is the high in strength alloy that possess hot and cold workability with good forging ability. The alloy is manufactured using the process of bending, coining, drawing and upsetting, hot forging and pressing, knurling, roll threading, shearing, spinning, swaging, and stamping.

Typical Uses :

Specifications |

Designation |

ISO |

CuAl8Fe3 |

European |

CuAl8Fe3 |

BSI |

AS 106 |

JIS |

C 6140 |

Product Property |

- |

Melting Point - Liquidus°F |

1652 |

Densitylb/cu in. at 68°F |

0.286 |

Specific Gravity |

7.92 |

Electrical Conductivity% IACS at 68°F |

22 |

Thermal ConductivityBtu/ sq ft/ ft hr/ °F at 68°F |

57 |

Coefficient of Thermal Expansion 68-57210?6 per °F (68 – 572°F) |

11.9 |

ROUND RODS |

8mm To 100 mm |

HEX |

10mm To 60mm |

SQUARE |

10mm To 60mm |

FLAT |

10mm Min Thickness and max Width 120mm |

BILLETS |

Up to 200 mm |

INGOTS |

As per Specification |

The C67300 manganese bronze is high in strength alloy with good bearing qualities. The alloy maintains high impact resistance with with good machinability by making it well suited for clutch bearings, shaft bushings, sleeve bearings, thrust bearings, pump parts, drive shafts, bearing pins, wear plates, gears and cams. It also resists squashing out under high loads and extreme wear applications.

The C67300 manganese bronze is high in strength alloy with good bearing qualities. The alloy maintains high impact resistance with with good machinability by making it well suited for clutch bearings, shaft bushings, sleeve bearings, thrust bearings, pump parts, drive shafts, bearing pins, wear plates, gears and cams. It also resists squashing out under high loads and extreme wear applications.

Typical Uses :

Specifications |

Designation |

UNS |

C66800 |

UNS |

C67400 |

UNS |

C67420 |

|

Al |

Cu |

Fe |

Pb |

Mn |

Ni |

Si |

Sn |

Zn |

Min/Max |

0.25 |

58.0 - 63.0 |

0.5 |

0.40 - 3.0 |

2.0 - 3.5 |

0.25 |

0.50 - 1.5 |

0.3 |

Rem |

Nominals |

- |

60.5000 |

- |

1.7000 |

2.7000 |

- |

1.0000 |

- |

34.1000 |

End Product |

Specification |

Bar |

SAE J461, J463 |

Forgings |

SAE J461, J463 |

Rod |

SAE J463, J461 |

Shapes |

SAE J463, J461 |

Joining Technique |

Suitability |

Machinability Rating |

70 |

Product Property |

US Customary |

Metric |

Coefficient of Thermal Expansion |

11 ·10-6 per oF (68-572 F) |

19.0 ·10-6 per oC (20-300 C) |

Density |

.30 lb/in3 at 68 F |

8.3 gm/cm3 @ 20 C |

Electrical Conductivity |

22 %IACS @ 68 F |

0.13 MegaSiemens/cm @ 20 C |

Melting Point - Liquidus |

1605 F |

874 C |

Modulas of Elasticity in Tension |

17000 ksi |

117200 MPa |

Specific Gravity |

8.3 |

8.3 |

Thermal Conductivity |

55 Btu · ft/(hr · ft2·oF)at 68F |

95.0 W/m · oK at 20 C |

ROUND RODS/BARS |

|

HEX |

10mm To 60mm |

SQUARE |

10mm To 60mm |

FLAT |

10mm Min Thickness and max Width 120mm |

BILLETS |

Up to 200 mm |

INGOTS |

As per Specification |

The C67400 manganese bronze alloy is manufactured using the process of bending, drawing, upsetting, and many other processes. The alloy is excellent on hot and cold workability and forge ability.

The C67400 manganese bronze alloy is manufactured using the process of bending, drawing, upsetting, and many other processes. The alloy is excellent on hot and cold workability and forge ability.

Typical Uses :

Specifications |

Designation |

UNS |

C66800 |

UNS |

C67300 |

UNS |

C67420 |

|

Al |

Cu |

Fe |

Pb |

Mn |

Ni |

Si |

Sn |

Zn |

Min/Max |

0.50 - 2.0 |

57.0 - 60.0 |

0.35 |

0.5 |

2.0 - 3.5 |

0.25 |

0.50 - 1.5 |

0.3 |

Rem |

Nominals |

1.2 |

58.5 |

- |

- |

2.8 |

- |

1 |

- |

36.5 |

End Product |

Specification |

Bar |

SAE J461, J463 |

Forging |

SAE J461, J463 |

Rod |

SAE J463, J461 |

Shapes |

SAE J463, J461 |

Joining Technique |

Suitability |

Brazing |

Good |

Butt Weld |

Good |

Capacity for Being Cold Worked |

Poor |

Capacity for Being Hot Formed |

Excellent |

Coated Metal Arc Welding |

Not Recommended |

Forgeability |

100 |

Gas Shielded Arc Welding |

Fair |

Machinability Rating |

30 |

Oxyacetylene Welding |

Not Recommended |

Seam Weld |

Good |

Soldering |

Fair |

Spot Weld |

Good |

Product Property |

US Customary |

Metric |

Coefficient of Thermal Expansion |

11.0 ·10-6 per oF (68-572 F) |

19.8 ·10-6 per oC (20-300 C) |

Density |

0.292 lb/in3 at 68 F |

8.08 gm/cm3 @ 20 C |

Electrical Conductivity |

23 %IACS @ 68 F |

0.135 MegaSiemens/cm @ 20 C |

Electrical Resistivity |

45.1 ohms-cmil/ft @ 68 F |

7.5 microhm-cm @ 20 C |

Melting Point - Liquidus |

1625 F |

885 C |

Melting Point - Solidus |

1590 F |

866 C |

Modulas of Elasticity in Tension |

16000 ksi |

110000 MPa |

Modulus of Rigidity |

6000 ksi |

41370 MPa |

Specific Gravity |

8.08 |

8.08 |

Specific Heat Capacity |

0.09 Btu/lb/oF at 68 F |

377.1 J/kg/ · oK at 293 K |

Thermal Conductivity |

58.0 Btu · ft/(hr · ft2·oF)at 68F |

100.4 W/m · oK at 20 C |

ROUND RODS |

8mm To 70 mm |

HEX |

10mm To 60mm |

SQUARE |

10mm To 60mm |

FLAT |

10mm Min Thickness and max Width 120mm |

BILLETS |

Up to 200 mm |

INGOTS |

As per Specification |

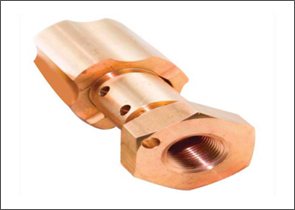

Alloy C67500 (CuZn37FeSnMn) is a wrought alloy with additions of iron, tin and manganese to increase the strength and corrosion resistance.

Alloy C67500 (CuZn37FeSnMn) is a wrought alloy with additions of iron, tin and manganese to increase the strength and corrosion resistance.

It can be worked to increase the strength and can be available in the half hard and fully hard condition.

It possess hot working properties and can be die forged into valves, connectors and other components for military applications. It can also be hot headed or upset forged for manufacturing fasteners.

Typical Uses :

|

Al |

Cu |

Fe |

Pb |

Mn |

Si |

Zn |

Min/Max |

0.25 |

57.0 - 60.0 |

0.80 - 2.0 |

0.2 |

0.05 - 0.50 |

0.50 - 1.5 |

Rem |

Nominals |

- |

58.5000 |

1.4000 |

- |

0.1000 |

1.0000 |

39.0000 |

End Product |

Specification |

Bar |

ASTM B138, SAE J461, J463 |

Bar, For ging |

ASTM B124 |

Bolts |

ASTM F468 |

Forgings, Die |

ASTM B283, SAE J463, J461 |

Nuts |

ASTM F467 |

Rod |

ASTM B138, SAE J463, J461 |

Rod, Forging |

ASTM B124 |

Screws |

ASTM F468 |

Shapes |

ASTM B138, SAE J461, J463 |

Shapes, Forging |

ASTM B124 |

Studs |

ASTM F468 |

Joining Technique |

Suitability |

Brazing |

Excellent |

Butt Weld |

Good |

Capacity for Being Cold Worked |

Poor |

Capacity for Being Hot Formed |

Excellent |

Coated Metal Arc Welding |

Not Recommended |

Forgeability |

80 |

Gas Shielded Arc Welding |

Fair |

Machinability Rating |

30 |

Oxyacetylene Welding |

Good |

Seam Weld |

Fair |

Soldering |

Excellent |

Spot Weld |

Good |

Product Property |

US Customary |

Metric |

Coefficient of Thermal Expansion |

11.8 ·10-6 per oF (68-572 F) |

21.2 ·10-6 per oC (20-300 C) |

Density |

0.302 lb/in3 at 68 F |

8.36 gm/cm3 @ 20 C |

Electrical Conductivity |

24 %IACS @ 68 F |

0.14 MegaSiemens/cm @ 20 C |

Electrical Resistivity |

43.2 ohms-cmil/ft @ 68 F |

7.18 microhm-cm @ 20 C |

Melting Point - Liquidus |

1630 F |

888 C |

Melting Point - Solidus |

1590 F |

866 C |

Modulas of Elasticity in Tension |

15000 ksi |

103400 MPa |

Modulus of Rigidity |

5600 ksi |

38610 MPa |

Specific Gravity |

8.36 |

8.36 |

Specific Heat Capacity |

0.09 Btu/lb/oF at 68 F |

377.1 J/kg/ · oK at 293 K |

Thermal Conductivity |

61.0 Btu · ft/(hr · ft2·oF)at 68F |

105.6 W/m · oK at 20 C |

ROUND RODS/BARS |

8mm To 70 mm |

HEX |

10mm To 60mm |

SQUARE |

10mm To 60mm |

FLAT |

10mm Min Thickness and max Width 120mm |

BILLETS |

Up to 200 mm |

INGOTS |

As per Specification |

The alloy possess excellent hot and cold workability; good forge ability. Fabricated by bending, coining, coppersmith, drawing and upsetting, hot forging and pressing, knurling, roll threading, shearing, spinning, swaging, and stamping.

The alloy possess excellent hot and cold workability; good forge ability. Fabricated by bending, coining, coppersmith, drawing and upsetting, hot forging and pressing, knurling, roll threading, shearing, spinning, swaging, and stamping.

Typical Uses :

|

Cu |

Fe |

Pb |

Mn |

Sn |

Zn |

Min/Max |

57.0 - 60.0 |

0.40 - 1.3 |

0.50 - 1.0 |

0.05 - 0.50 |

0.50 - 1.5 |

Rem |

Nominals |

58.5 |

0.8 |

0.7 |

0.27 |

1 |

38.7 |

End Product |

Specification |

Brazing Filler Metal |

AWS A5.8 |

Forgings, Die |

ASTM B283 |

Joining Technique |

Suitability |

Brazing |

Excellent |

Capacity for Being Cold Worked |

Poor |

Capacity for Being Hot Formed |

Excellent |

Forgeability |

80 |

Gas Shielded Arc Welding |

Fair |

Machinability Rating |

60 |

Oxyacetylene Welding |

Good |

Soldering |

Excellent |

Spot Weld |

Good |

Product Property |

US Customary |

Metric |

Coefficient of Thermal Expansion |

11.8 ·10-6 per oF (68-572 F) |

20.4 ·10-6 per oC (20-300 C) |

Density |

0.302 lb/in3 at 68 F |

8.36 gm/cm3 @ 20 C |

Electrical Conductivity |

24 %IACS @ 68 F |

0.139 MegaSiemens/cm @ 20 C |

Melting Point - Liquidus |

1630 F |

890 C |

Melting Point - Solidus |

1590 F |

865 C |

Modulas of Elasticity in Tension |

15000 ksi |

103400 MPa |

Modulus of Rigidity |

5600 ksi |

38600 MPa |

Thermal Conductivity |

61.0.0 Btu · ft/(hr · ft2·oF)at 68F |

105.7 W/m · oK at 20 C |

ROUND RODS/BARS |

8mm To 70 mm |

HEX |

10mm To 60mm |

SQUARE |

10mm To 60mm |

FLAT |

10mm Min Thickness and max Width 120mm |

BILLETS |

Up to 200 mm |

INGOTS |

As per Specification |

The Manganese bronze - copper casting alloy UNS C86200 consists primarily of copper, zinc, aluminum and manganese bronze. Manganese existing in UNS C86200 provides an attractive chocolate brown color which is commonly used in architecture. The presence of lead in the alloy improves the longevity of the alloy.

The Manganese bronze - copper casting alloy UNS C86200 consists primarily of copper, zinc, aluminum and manganese bronze. Manganese existing in UNS C86200 provides an attractive chocolate brown color which is commonly used in architecture. The presence of lead in the alloy improves the longevity of the alloy.

Typical Uses :

Specifications |

Designation |

UNS |

C86200 |

ISO |

CuZn26Al4Fe3Mn3 |

JIS |

CAC303 |

|

Zn |

Cu |

Fe |

Mn |

Ni |

Pb |

Sn |

Min/Max |

22-28 |

60-66 |

2-4 |

2.5-5 |

1.0max |

0.2max |

0.2 max |

Nominals |

25 |

63 |

3 |

3.7 |

- |

- |

- |

Product Property |

US Customary |

Melting Point - Liquidus |

1725 F |

Melting Point - Solidus |

1650 F |

Density |

0.288 lb/in3 at 68 F |

Specific Gravity |

7.97 |

Electrical Resistivity |

136.70 ohms-cmil/ft @ 68 F |

Electrical Conductivity |

8 %IACS @ 68 F |

Thermal Conductivity |

20.50 Btu · ft/(hr · ft2·°F)at 68F |

Coefficient of Thermal Expansion |

120 ·10-6 per oF (68-392 F) |

Specific Heat Capacity |

0.090 Btu/lb/°F at 68 F |

Modulas of Elasticity in Tension |

15000 ksi |

Magnetic Permeability* |

1.24 |

ROUND RODS/BARS |

8mm To 70 mm |

HEX |

10mm To 60mm |

SQUARE |

10mm To 60mm |

FLAT |

10mm Min Thickness and max Width 120mm |

BILLETS |

Up to 200 mm |

INGOTS |

As per Specification |